3D milling

Exact DMU Technology that Really Works Technology of the highest quality, developed and manufactured in Europe. Commonly used in Scandinavia, where it has become the industry standard. Tested and approved by the Swedish Ministry of Transport.

Assembly

3D milling

Virtual Ski

Slope replicator

Slope Informer

Job report

Key Benefits of the Exact Street DMU

- Reliable Performance, Even Under Bridges and in Tunnels: Operates flawlessly without a GPS signal (patent pending).

- Unmatched Accuracy: Achieves exceptional precision and stability, powered by advanced algorithms.

- Developed with Leading Institutions: Designed in collaboration with European science organizations and the European Space Agency.

- Multi-Software Integration: Combines various software applications into one powerful hardware solution.

- Made in Europe: 100% developed and manufactured in the EU.

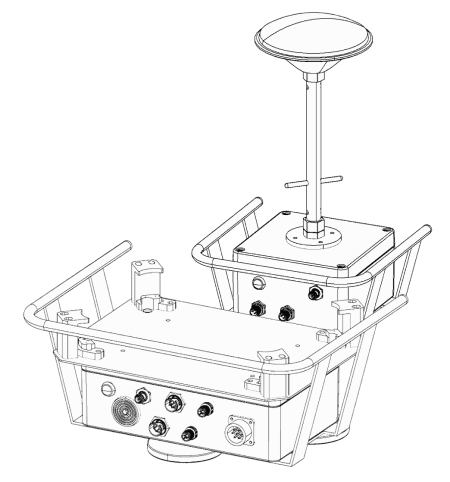

Assembly and Installation

Machine Control System for Precise and Efficient Road Milling

- Two Boxes Only: 2x GPS, 1x Control Unit, 2x Cables

- Installation Time: 10 minutes

- Powered by the Milling Machine

- Robust Stainless Steel/Aluminimu Chassis

- Dust proof, water proof, Bullet proof

- Total Weight: 17 kg

3D milling

Exact 3D Milling uses GPS positioning for millimeter-precise depth and slope control.

- Fully automated operation: No need for a surveyor or expert—just turn it on and start milling. The system automatically adjusts depth and slope based on a pre-calculated 3D model.

- Flexible data input: Create 3D models from survey data, CAD files, or road scans.

- Easy data transfer: Upload data remotely from the cloud or via a memory stick.

- User-friendly: Quick to learn and simple to use.

- Flexible operation: Start or restart milling anytime from anywhere.

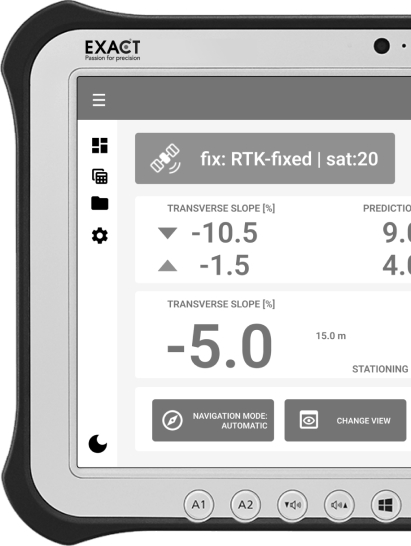

Exact Virtual Ski

Machine Control System for Precise and Efficient Road Milling

Usage:

- Projects where 'full' 3D milling is not required by the client (MTO, DoT, general contractor), or where the slopes of the existing road do not require correction or can be handled manual

- where there is no time to prepare precise 3D models for 3D milling

Main advantages of Exact Virtual Ski:

- Improves longitudinal smoothness (reduces IRI)

- Reduces the risk of diamond grinding repairs

- Reduces trucking costs by approximately 20-30% (reprofiling will normally reduce milling depth)

- will reduce the risk of breaking into the subgrade or granular (less milling in the low spot)

- Reduces the amount of new asphalt to be paved (no need to compensate for unevenness with new asphalt)

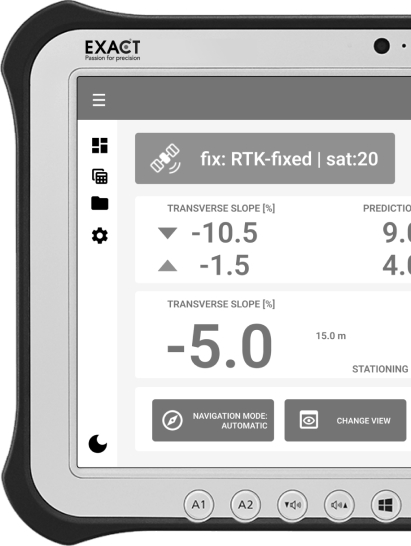

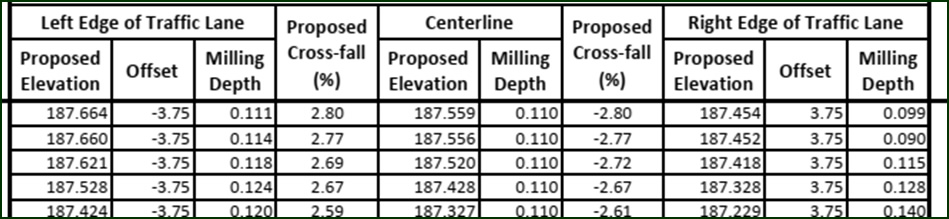

Slope Informer

The software modules are designed to ensure that the strict requirements of the Cross Slope Tolerance Specification are met.

For example, project documentation input in the form of STA and slopes can be directly entered into the unit via the Slope Informer software module (either manually or uploaded as a file). The Exact DMU then automatically completes and interpolates the parameters, continuously providing and controlling the proposed cross-fall during milling or paving.

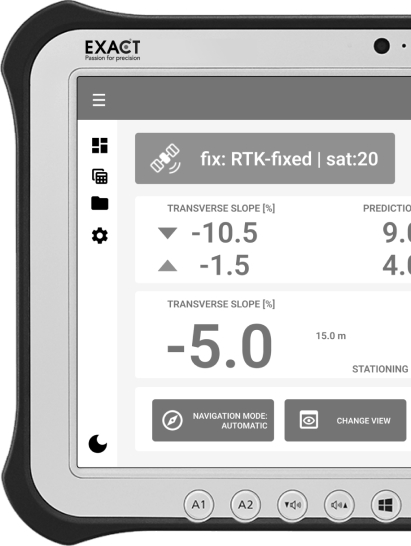

Slope replicator

Replication of cross slopes enables real-time, automatic replication of milling machine cross slopes from individual milling runs.

- Precise Profile Replication: Achieve perfect and consistent slopes with millimeter accuracy.

- Efficient Milling: Minimize unnecessary milling and optimize material consumption.

- Increased Productivity: The automated process eliminates manual adjustments and reduce milling time.

- Increased Safety: Eliminate the risk of human error and ensure optimal drainage profiles.

Job report

Management and analysis of data recorded

The Job Report app is designed for the management and analysis of data recorded by DMU system during milling operations. It enables efficient viewing and evaluation of data in various formats, including maps, stationing, cross and longitudinal sections, axis, and area.

- Georeferencing: Data are georeferenced using a GPS tracker, ensuring accurate localization and spatial analysis in various CAD or GIS software.

- Productivity Metrics: Generate comprehensive reports summarizing area, slopes, time, and productivity metrics for thorough analysis.

- Customizable Insights: Tailor reports to your specific needs, focusing on metrics that matter most to your operations.